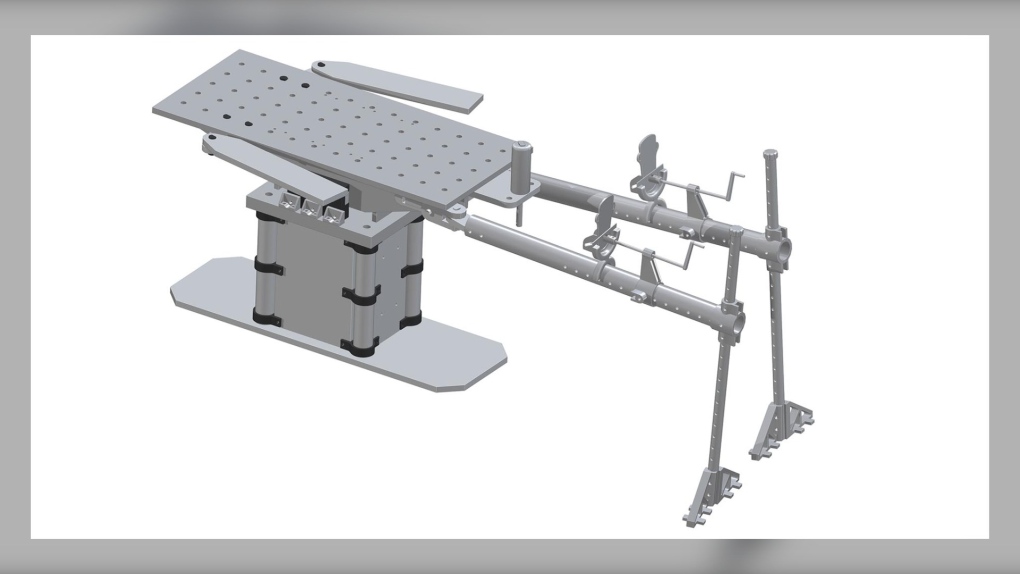

Western University helps develop 3D-printed surgical table

3D-printed surgical table. (Source: Western University)

3D-printed surgical table. (Source: Western University)

A collaborative project between Western University and Michigan Tech University has resulted in a functional, 3D-printed surgical fracture table.

According to Western, the table was built at a fraction of what it would normally cost.

“We want everyone in the world to have cost-effective medical care and this is one step on the path to getting us there,” said Joshua Pearce, chair in Information Technology and Innovation at Western. “And if we help those who are financially less fortunate with acquiring high-performance medical equipment, we will also be making better medical tools for ourselves at a lower cost, so really, everyone wins.”

The capital cost of a surgical fracture table, for example, would generally cost more than $250,000. The final constructed operating table costs just under $4,000, or a 98.5 per cent savings compared to commercially available systems.

The study could have significant impact in the developing world, according to Western, where the financial burden of medical equipment is a significant barrier to universal access to health care.

Final assembly of surgical fracture table. (Source: Western University)“Medical technology is absurdly expensive. One way we can help reduce costs is to enable all manufacturers to build these, sell them directly, and to integrate some of the innovations, like the use of the radiolucent 3D-printed parts we made into their own designs,” said Pearce. “This is in no way the final fracture table. I’m sure any decent engineer could look at it and make it a little bit better and that’s exactly what it’s meant to do — to be a starting point for other people to build on.”

Final assembly of surgical fracture table. (Source: Western University)“Medical technology is absurdly expensive. One way we can help reduce costs is to enable all manufacturers to build these, sell them directly, and to integrate some of the innovations, like the use of the radiolucent 3D-printed parts we made into their own designs,” said Pearce. “This is in no way the final fracture table. I’m sure any decent engineer could look at it and make it a little bit better and that’s exactly what it’s meant to do — to be a starting point for other people to build on.”

Ideally, this table design is useful to hospitals that might otherwise be unable to afford one, reads a statement from Western.

As the design of the table is freely available, the table can be built, used and repaired on location. As surgeons and other health-care workers find a need for further attachments and modifications, they can add to the functionality of the design, either by designing a modification themselves, or by describing what they would like to see in the design and having others contribute to these designs.

The work was published in the high-impact journal PLOS ONE, outlining innovative, step-by-step, techniques to build a functionally comparable operating table using open-source hardware and 3D printing.

CTVNews.ca Top Stories

Canada Post presents union with 'framework' to reach deal as strike continues

Canada Post says it has presented the union representing some 55,000 striking postal workers with a framework to reach negotiated agreements.

PM Trudeau 'surprised' provinces unanimous on accelerated defence spending: Ford

Ontario Premier Doug Ford says his fellow provincial leaders are united in pushing for Canada to meet its NATO defence spending targets ahead of schedule, and that Prime Minister Justin Trudeau was "surprised" to hear it.

One man dead after shooting at Kitchener's 'A Better Tent City'

One man is dead after an afternoon shooting at 49 Ardelt Ave. in Kitchener.

Poilievre calls for asylum seeker cap, border plan as U.S. tariff threat looms

Conservative Leader Pierre Poilievre has demanded the federal government present a plan before Parliament to beef up border security as U.S. president-elect Donald Trump threatens to impose stiff tariffs on Canada.

developing Emergency crews battle large fire at Kitchener, Ont. townhouse complex

Waterloo Regional Police say Kingsway Drive is closed as emergency services respond to a fire at a townhouse complex.

Watch: Noisy throng of sea lions frolic near Jericho Beach

A large swarm of California sea lions have converged in the waters near Vancouver’s Jericho and Locarno beaches.

Stellantis CEO Carlos Tavares resigns as carmaker continues to struggle with slumping sales

Stellantis CEO Carlos Tavares is stepping down after nearly four years in the top spot of the automaker, which owns car brands like Jeep and Ram, amid an ongoing struggle with slumping sales.

'Moana 2' sails to a record US$221 million opening as Hollywood celebrates a moviegoing feast

'Moana 2' brought in a tidal wave of moviegoers over the Thanksgiving Day weekend, setting records with $221 million in ticket sales, according to estimates.

Immigrants take to the streets to protest against the freezing of immigration programmes

In response to the freeze on immigration programmes announced by Ottawa, an organization that defends the rights of immigrants is organising a demonstration in front of the Montreal office of the Quebec Ministry of Immigration, Francisation and Integration early on Saturday afternoon.