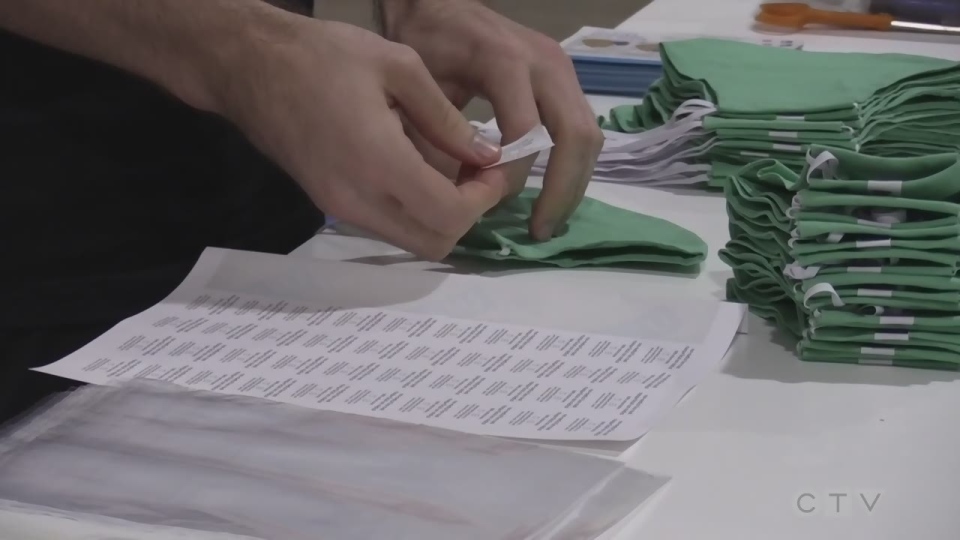

LONDON, ONT. -- Making up to 6000 reusable masks a week has become the norm at Goodwill Industries manufacturing facility on Whiteoaks Road in South London.

“Typically it takes six to eight months to launch what we did with face masks and we did it within two to three weeks, we were up and running fairly quickly,” says Hassan Habash from Goodwill Industries.

Right before the pandemic hit, Fanshawe College and Goodwill were working to launch a social enterprise called Worth, which would re-purpose donations that weren’t selling at Goodwill. However plans changed with COVID-19.

“It was phenomenal to see everyone come together so quickly to pivot, that’s been our key word, to pivot so quickly to get the face masks researched, designed and ready for manufacturing,” says Habash.

More than a dozen people were hired to help manufacture the masks, Habash says many are new Canadians.

“The amazing part about it was we were able to provide meaningful work to newcomers to Canada as well as Fanshawe students who needed it got their co-op program.”

Jennifer Wright, a professor from Fanshawe College has been working along side Habash and his team to help with the new mask venture.

“Creating jobs in a safe environment physically but also allowing people to work in the comfort of their own home so that they can look after their children, so they can look after their parents and so they can choose the hours they can work,” says Wright.

The team manufactures three types of masks; the worker mask, which is meant for longer wear, the commuter mask and the learner mask for children.

“The key to a good mask is not only the material it is made out of but also the fit close to your face.”

Wright says the masks made here have been through testing to ensure quality and effectiveness

“We also sent our masks for laboratory testing. Where they’ve tested incredibly well for breathability, they are right where they are supposed to be,” says Wright. “They are also testing very well for particulate filtration, which is putting them at the same level as a medical surgical mask worn at the hospital.”

Masks aren’t the only new product being manufactured by the team, they’re also bottling hand sanitizer for a company out of Mississauga called Progressive Industrial Fluids.

“They needed help bottling hand sanitizer so we quickly were able to retool our operation and set up and start bottling hand sanitizer for resale,” says Habash.

Both the masks and sanitizer are available at Goodwill stores and online.